LCM specialise in providing “Turn-key” bespoke Robot & Automation systems to our manufacturing and production clients. This is complemented with our Assembly Tooling, Jigs, Fixtures and Innovative Special Purpose machines.

Serving wider general industries and specialising in Automotive Sector we are able to design and build dedicated solutions ranging from Assembly Fixtures right through to complete Automated Robot Systems.

LCM have a long established track record of delivering diverse and complex systems within tight timescales, tackling a wide range of assembly and processing applications.

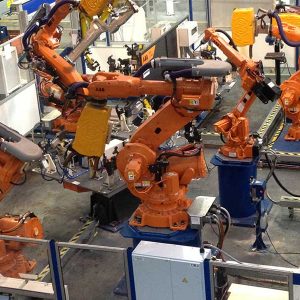

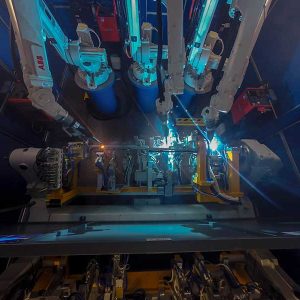

Robot Solutions & Automation

Automated applications using a wide range of technologies.

Fully integrated solutions delivered to our clients in a seamless “Turn-key” contract including;

- Robot automation – System integration – PLC programming

- Resistance Spot Welding

- Robot MIG welding

- Metal forming, Riveting, Clinching, Press Insertion

- Bonding, Gluing & Sealant Applications

- End of line inspection & testing

- Packaging & handling Solutions

- BIW, Chassis & Suspension, Closures, Final & General Assembly

Designed and engineered to suit your specific requirements

Systems completed with full In-House Testing, Development & Commissioning

Full installation service supplied at the clients facility right through to production launch.

Supported with CE certification, User Manual and Documentation

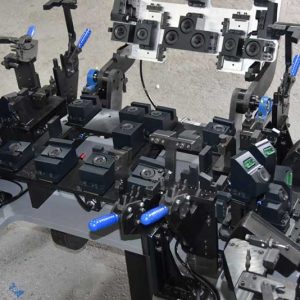

Tooling:

LCM provide a wide range of Tooling solutions including Production Assembly Tools, Jigs and Fixtures, where we specialise in providing an affordable complete turn-key service for clients demanding Premium Quality assembly tooling and fixture solutions.

Whether this is part of our Robot & Automated services, or provided as a dedicated tooling solution, LCM pride ourselves on providing the complete Design and Manufacturing service & experience. Unlike many other companies we are not reliant on sub-contracting Manufacture & Build, where we are proud to provide a dedicated service using our own extensive internal fabrication and machining facilities.

Our solutions and Designed & Developed using the latest technology in 3d modelling & Design simulations, LCM work closely with our clients to ensure their requirements are achieved for; quality, reliability and functionality for the specific application

- Manually & Automated fixtures

- Geometry Assembly fixtures for most processes

- Fine Limit or large Scale Holding devices

- Robot Handling & Robot end effectors

- Special purpose fixture applications

- Bespoke tooling & Special Purpose machine applications

Just some of our

CLIENTS

CONTACT US:

For more information and specific requests, our dedicated and experienced team are on hand to deal with all your enquiries.